Safety margins

Safety margins provide buffer time beyond the normal lead time.

For example, if a received product requires inspection, handling, or is otherwise delayed and not ready for immediate consumption, with a safety margin, you don’t need to add to the purchase lead time with the vendor because that would give that extra lead time to the vendor.

Safety margins are used in calculations for three services:

- Receipt margin – The buffer time for handling an incoming order.

- Reorder margin – The buffer time for placing a supply order.

- Issue margin – The buffer time for handling outgoing shipments.

An example of the margins that are used in calculations are shown in the following table.

| Event | # Days | Dates |

|---|---|---|

| Order date | July 1 | |

| Reorder margin | 2 | July 3 – Supply start date |

| Lead Time | 5 | July 8 – Supply delivery date |

| Receipt margin | 2 | July 10 – Supply requirement date |

| Issue margin | 3 | July 13 – Demand requirement date |

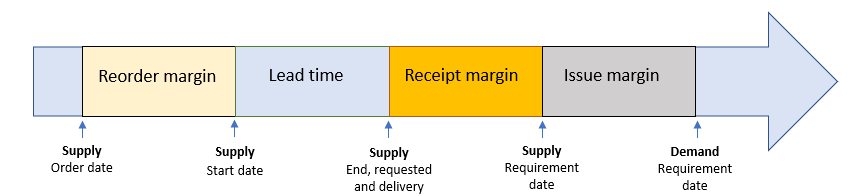

When the reorder and issue margin are enabled for master planning, the represented dates are as listed in the following diagram.

The margins become a part of lead time calculation.

Safety margins can be set up on the Coverage group and the Master plan. If safety margins are entered in both, they're added on top of each other. Thus, if you enter two days in the Coverage group and two days on the Master plan, it's a four-day margin.