Using the Withdrawal kanban for raw material replenishment

A new feature that enables advanced warehouse processes for the Withdrawal Kanban has been released together with KB 4016114 for AX2012. The feature is general available for Dynamics 365 for finance and operations.

Previously, the Withdrawal kanban could only transfer a material between fixed locations. Now it’s possible to release a withdrawal kanban for picking to a warehouse that is managed with flexible location storage. This feature introduces the following capabilities

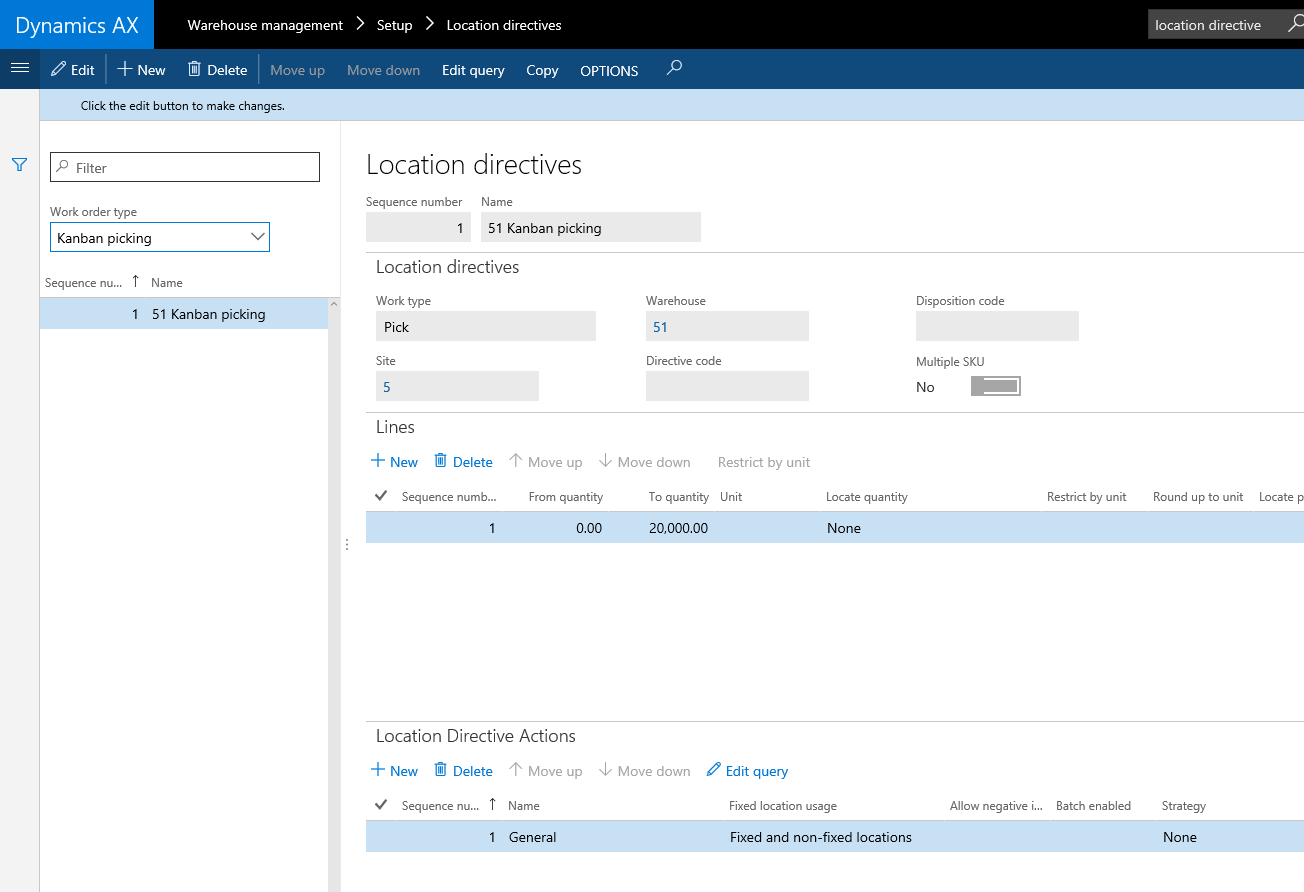

- Enable the user to configure warehouse processes for raw material picking for the withdrawal Kanban with the help of work templates and location directives.

- Enable the user to process work for raw material picking for the withdrawal Kanban with the hand-held device

- Enable the user to process an Empty Kanban signal with the hand-held device

- Provide the user a status of wave and work in the Picking list section in the Kanban transfer board.

- Enable the user to configure the Kanban transfer activity of the withdrawal Kanban to be automatic completed, when the Kanban pick work is completed.

In the following section, it is described in detail how a withdrawal Kanban is set up for material replenishment, for material that is managed on a warehouse for advanced warehouse processes.

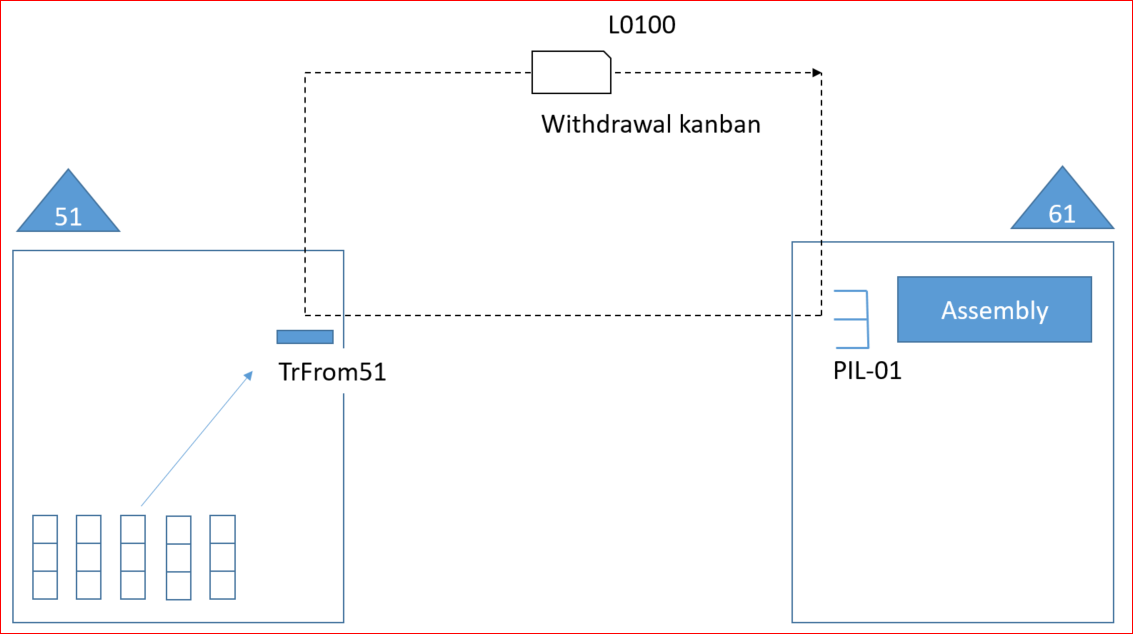

Scenario

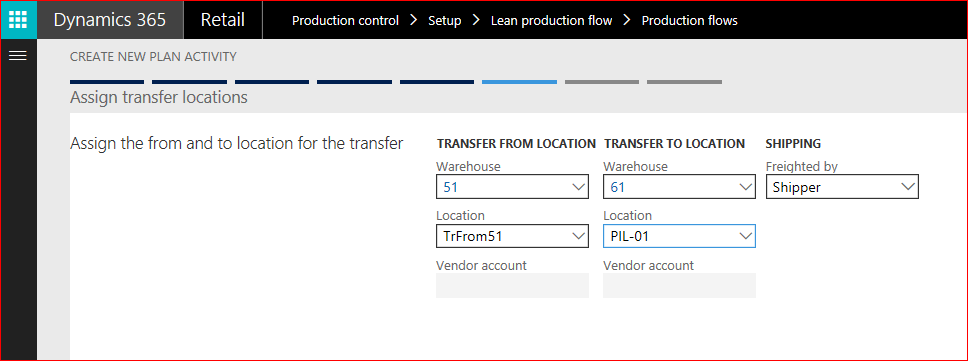

A withdrawal Kanban is set up to transfer material L0100 between locations in warehouse 51 to a production input location 001 in warehouse 61. When a new Kanban is created, the Kanban is automatically released to a wave in warehouse 51. When the wave is processed, warehouse work for Kanban picking is generated, directing the warehouse worker to pick L0100 on a location in warehouse 51 and put it to the TrFrom51 location. The Withdrawal Kanban is now ready to be completed. In the Complete step the material is transferred from location TrFrom51 in warehouse 51 to the production input location 001 in warehouse 61.

Prepare the demo

Use company USMF

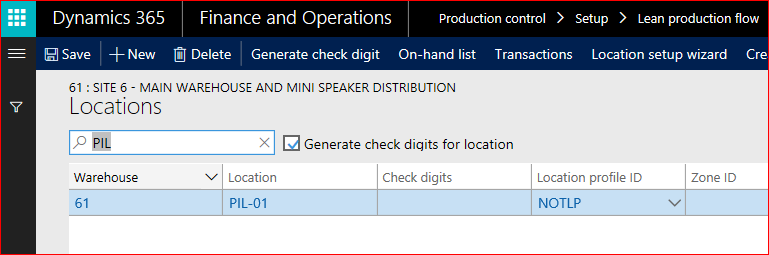

Create production input location PIL-01 in warehouse 61.

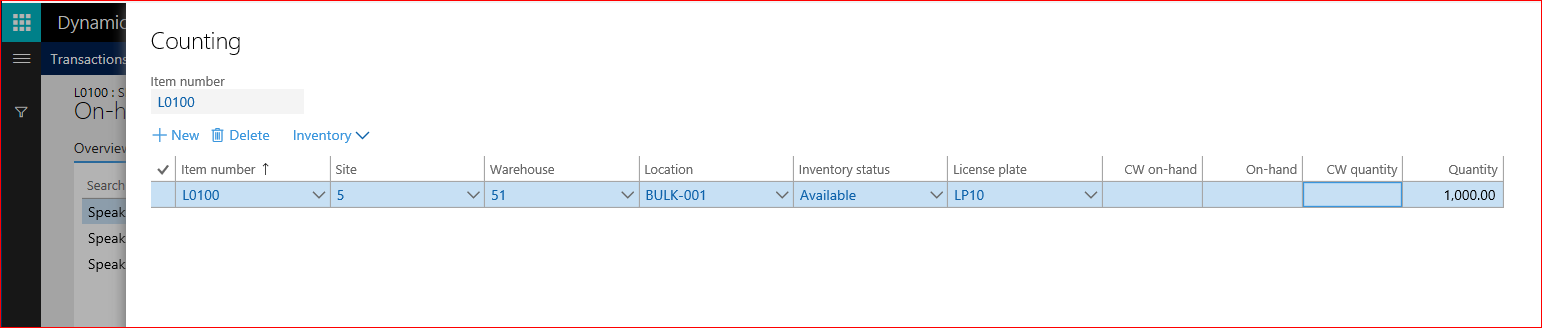

Add on-hand inventory for item L0100 in warehouse 51.

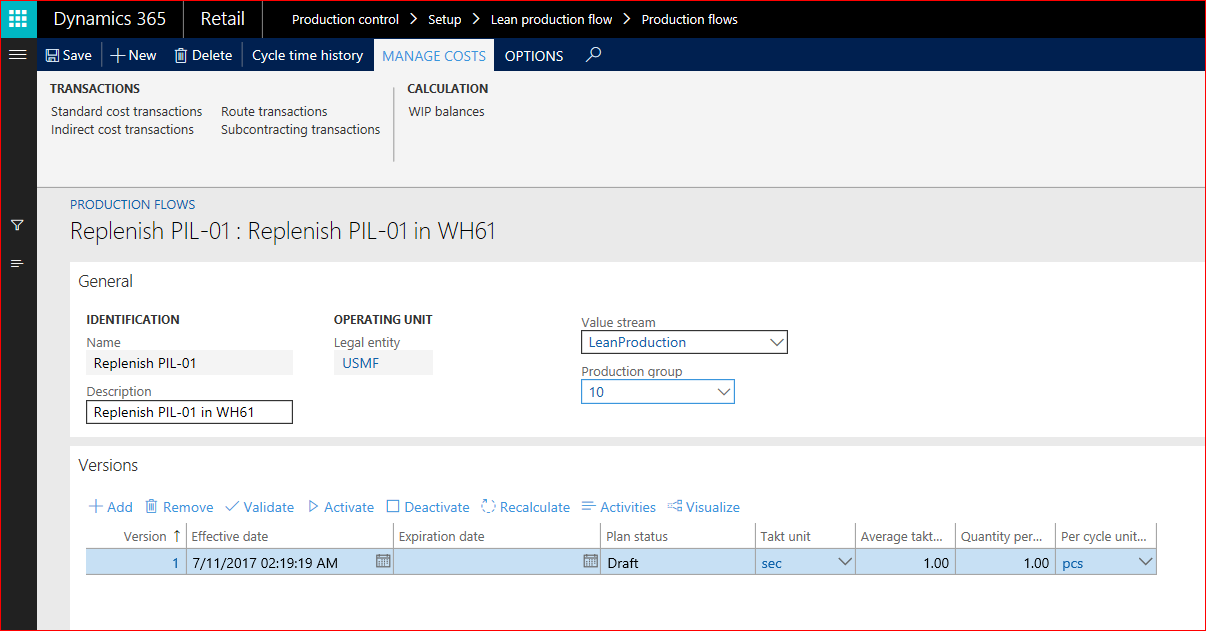

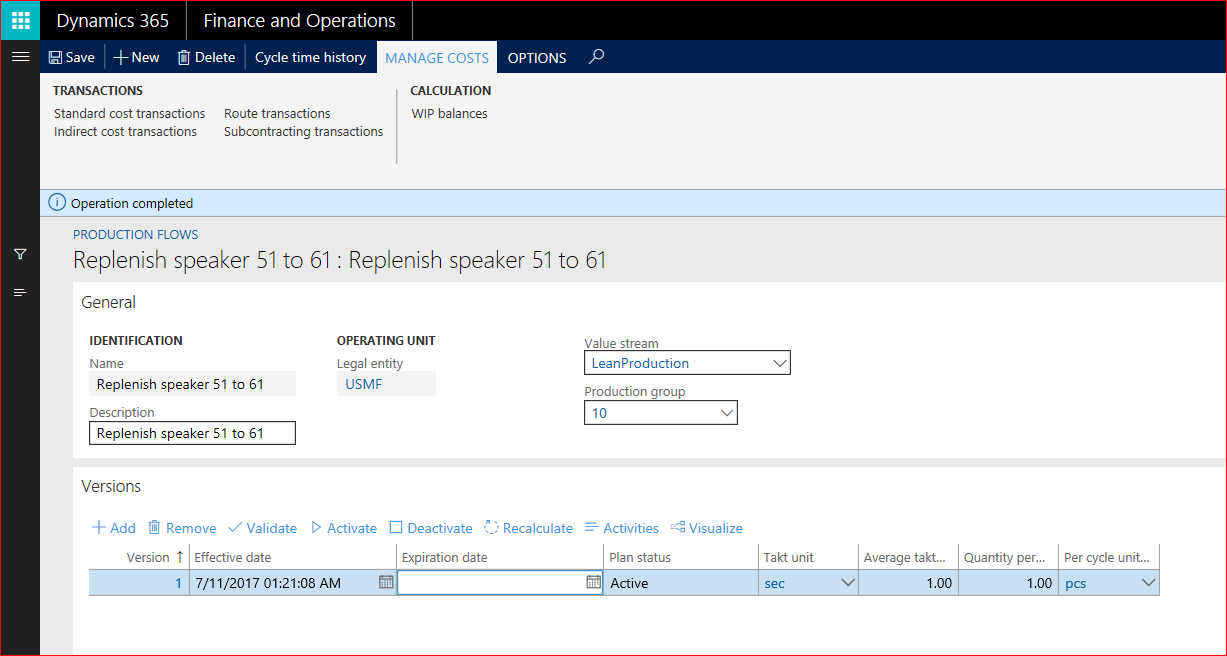

Create a new Lean production flow for transferring L0100 from warehouse 51 to warehouse 61.

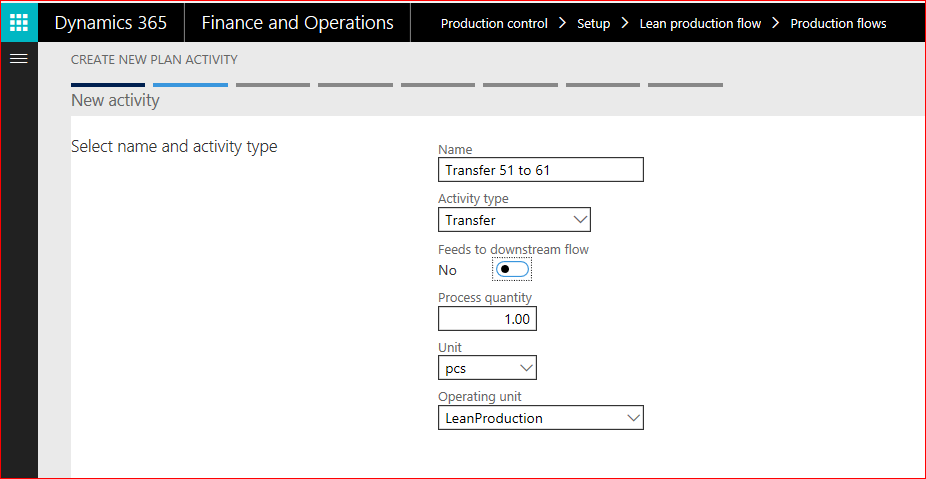

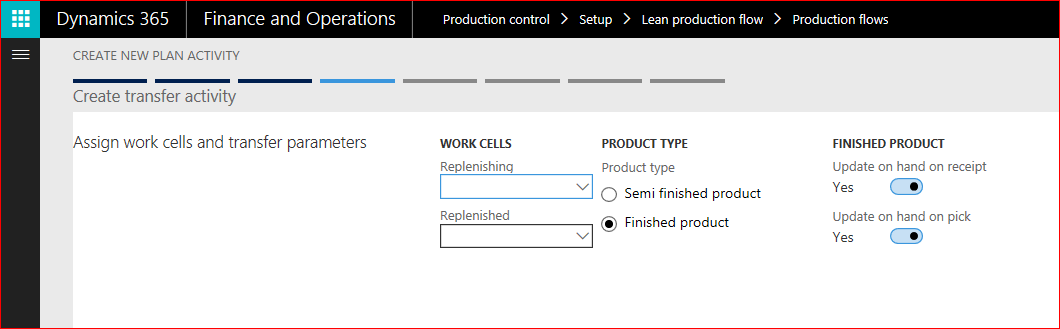

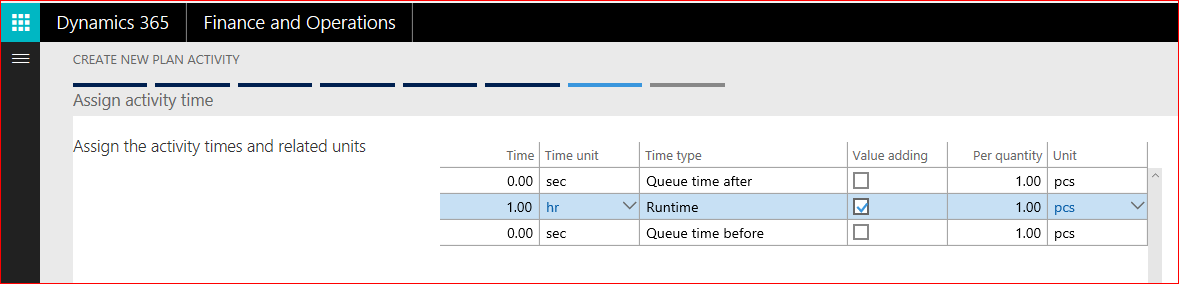

Define transfer activity

(Click: Activities -> Create a new activity plan -> Follow the wizzard)

Activate the flow

(Click: Activate)

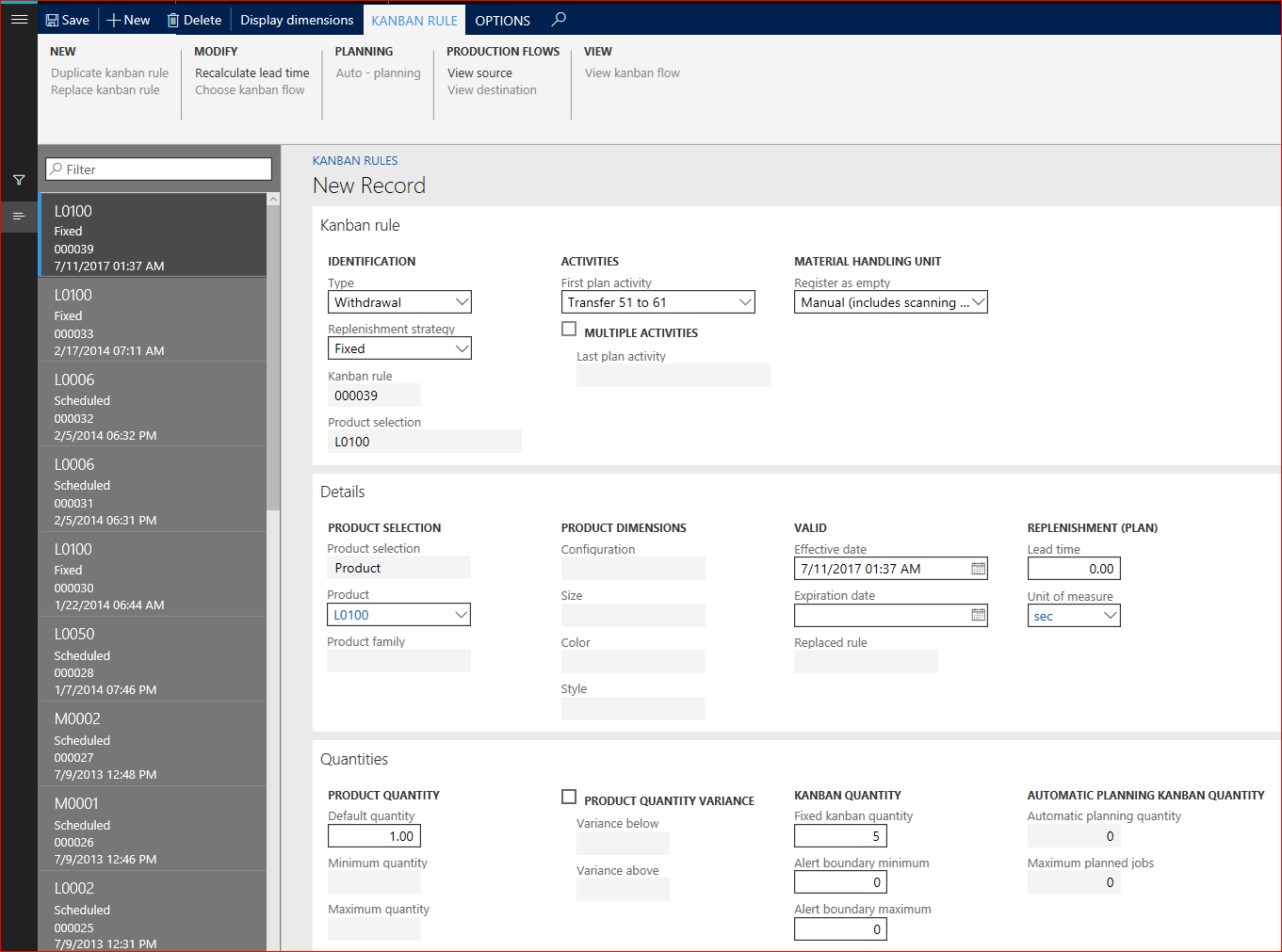

Create a Kanban rule for L0100

- Type: Withdrawal

- Replenishment strategy: Fixed

- First plan activity: Transfer 51 to 61

- Product: L0100

- Default quantity: 1

- Fixed Kanban quantity: 2

Check location directive for Kanban picking

Note: The two types of kanbans Manufacturing Kanban and Withdrawal Kanban shares the same location directive and work template. If separate processes for the two types of kanbans is required, then the configuration can be separated in the queries for work templates and location directive by filtering on the Kanban activity type (Transfer or process).

Demo

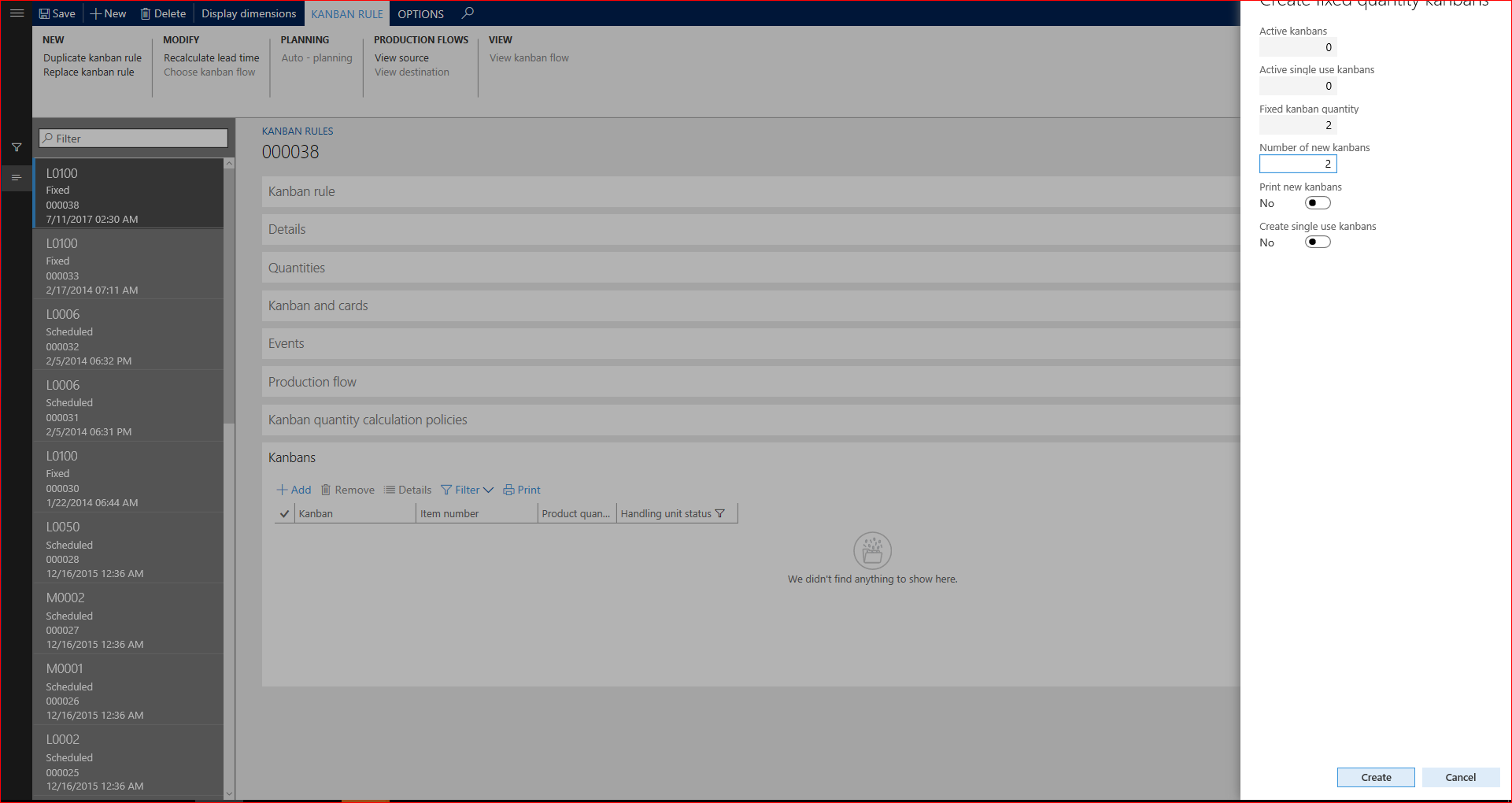

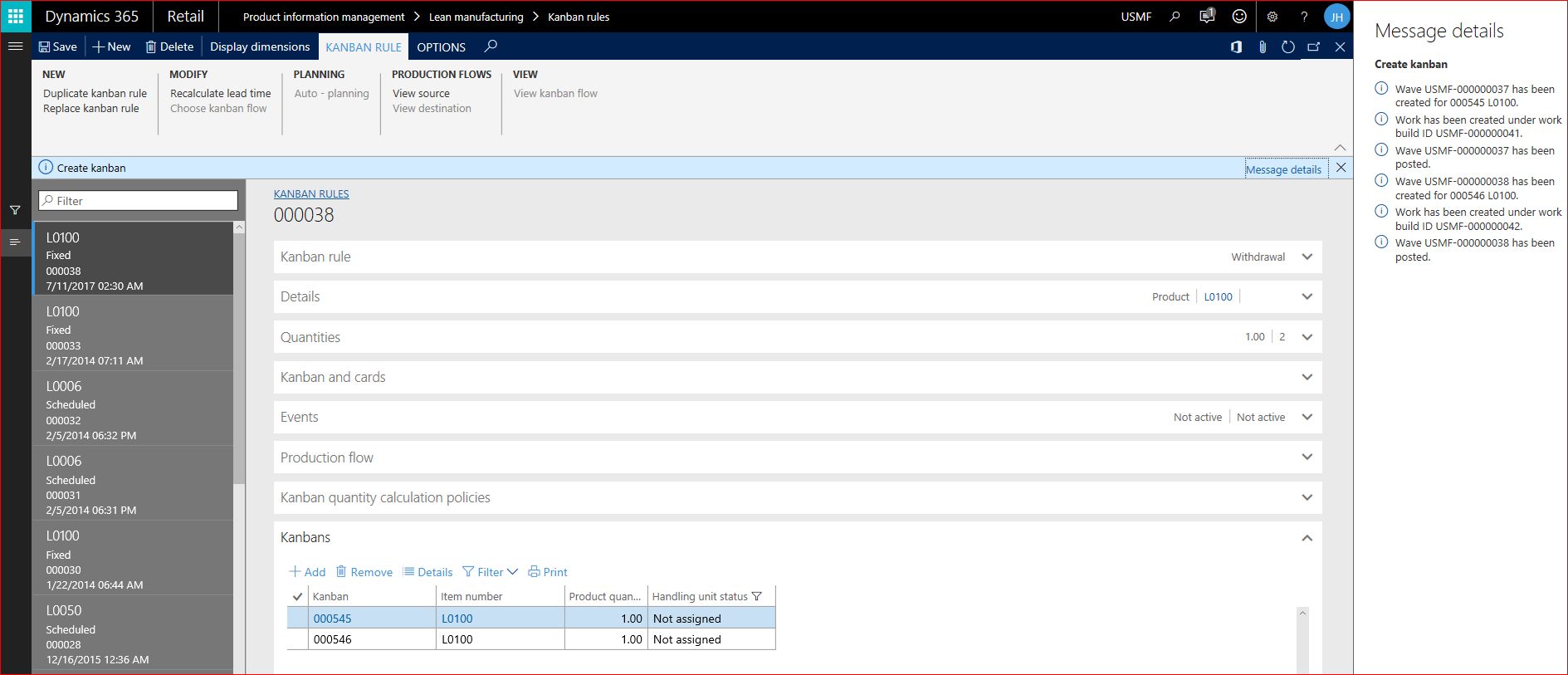

From the Kanban rule create two new Withdrawal kanbans for L0100

Note: After the Kanban’s are created, you can see from the message details that the Kanban’s have been released to a wave and warehouse work has been created.

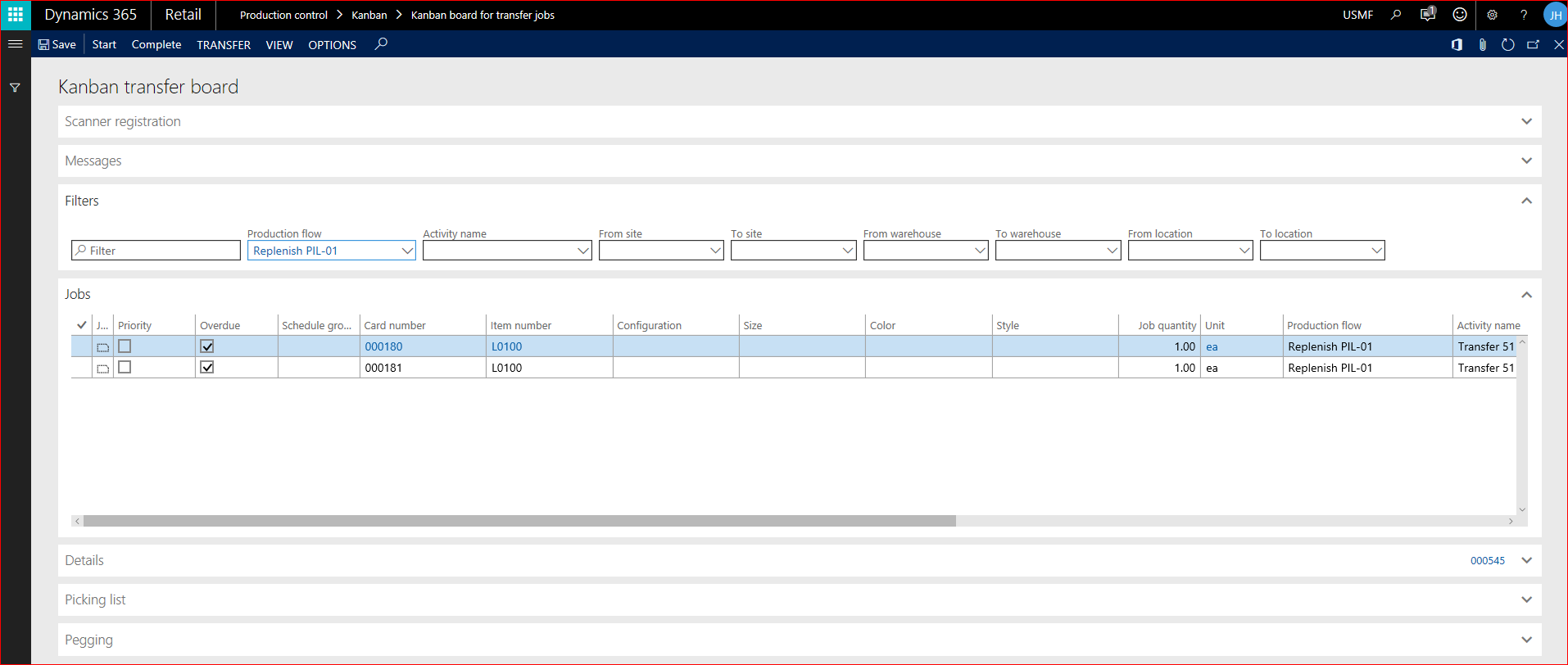

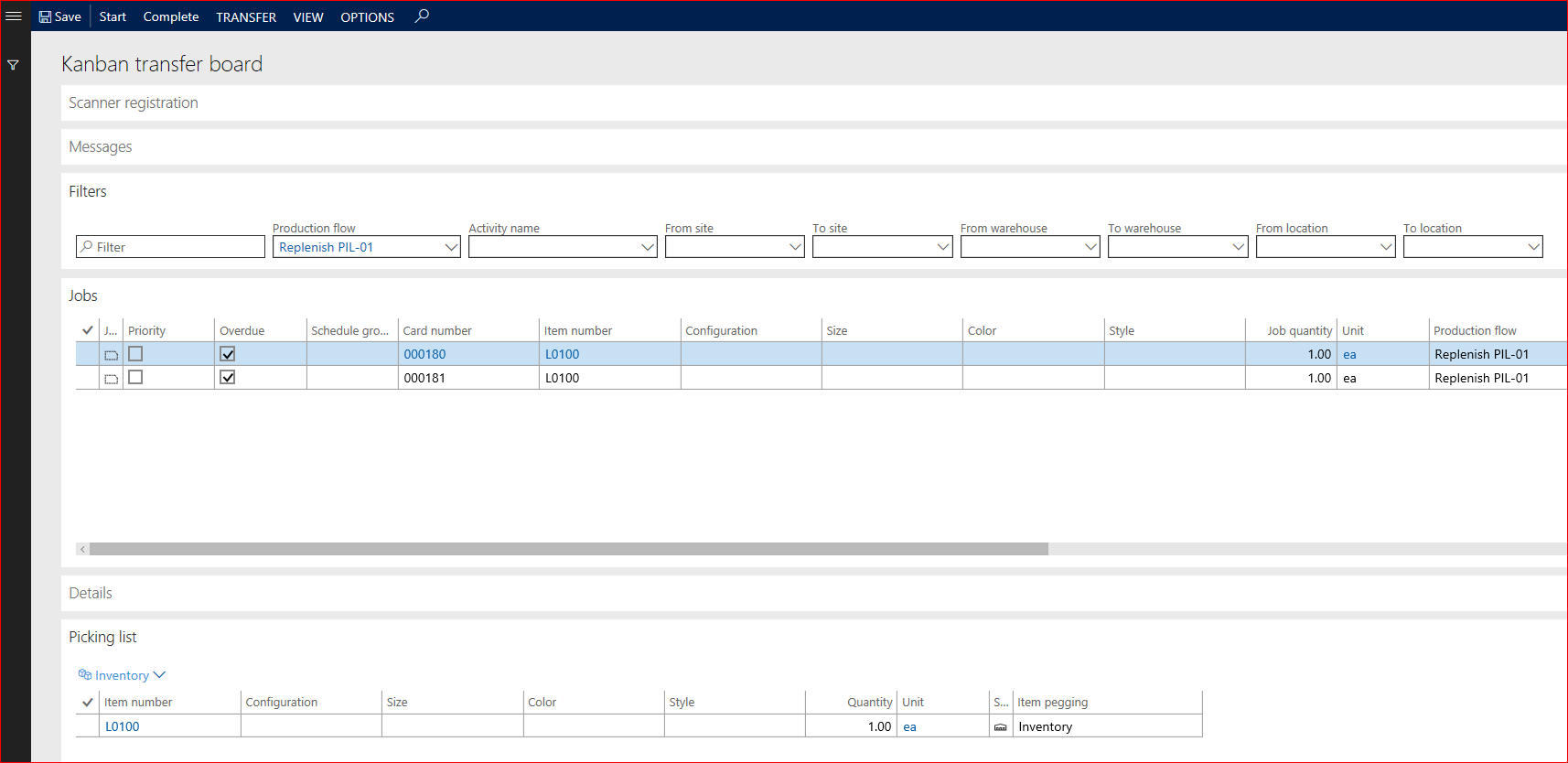

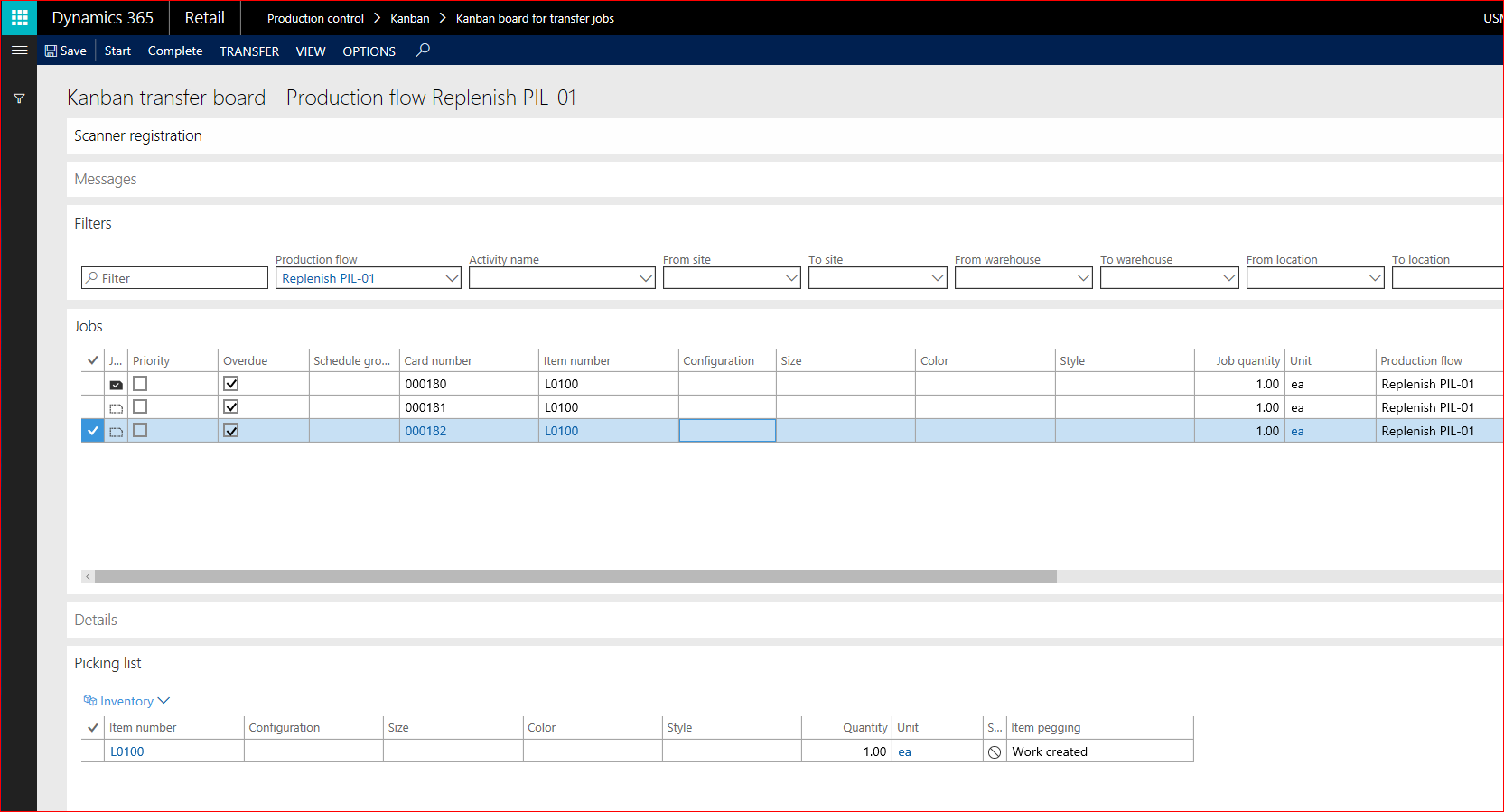

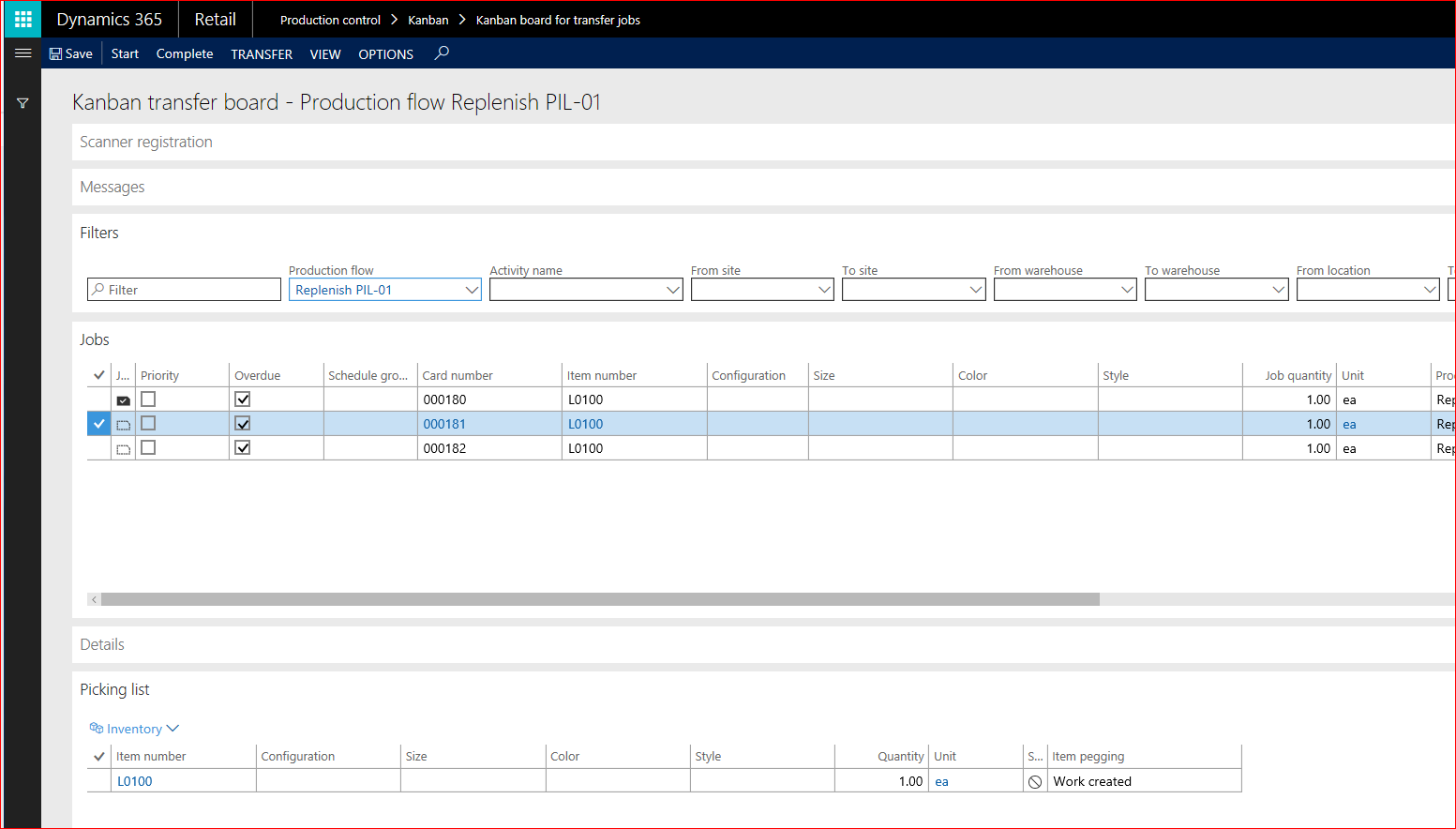

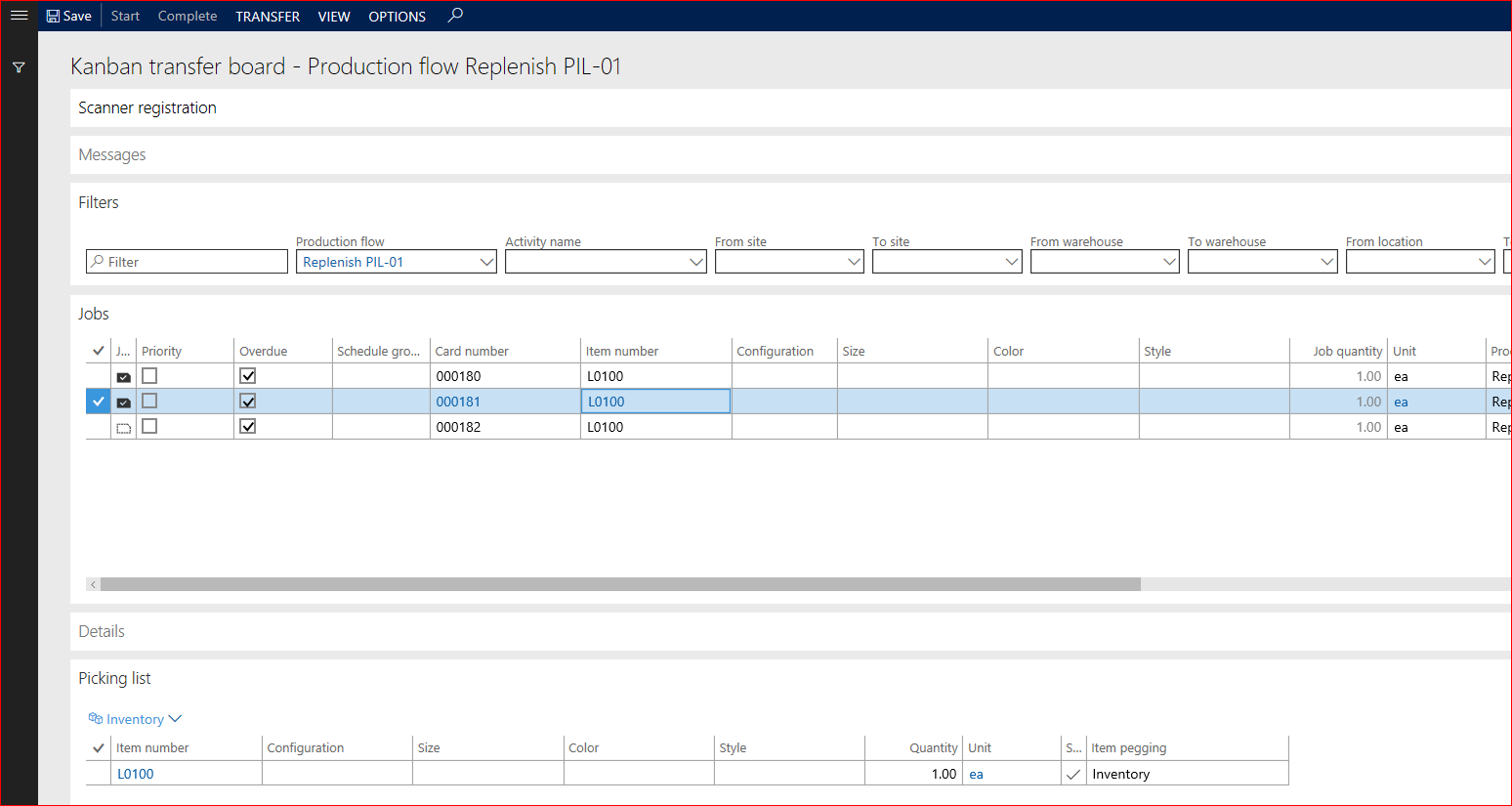

Go to the Kanban board for transfer jobs to see the details for the two Withdrawal kanbans. Filter on the production flow created for this scenario

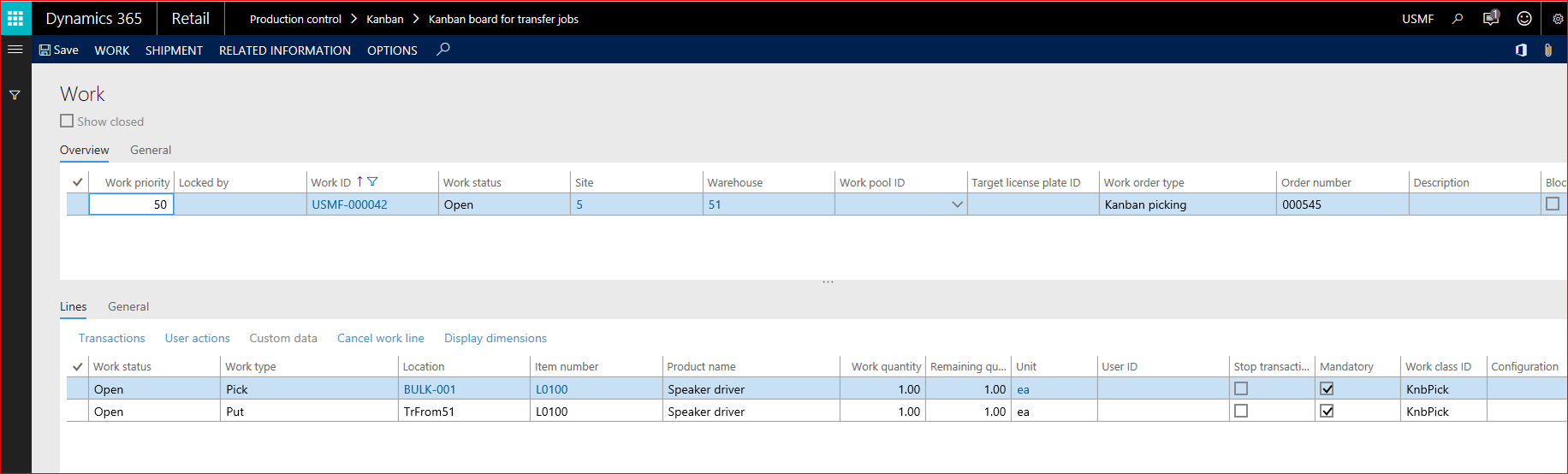

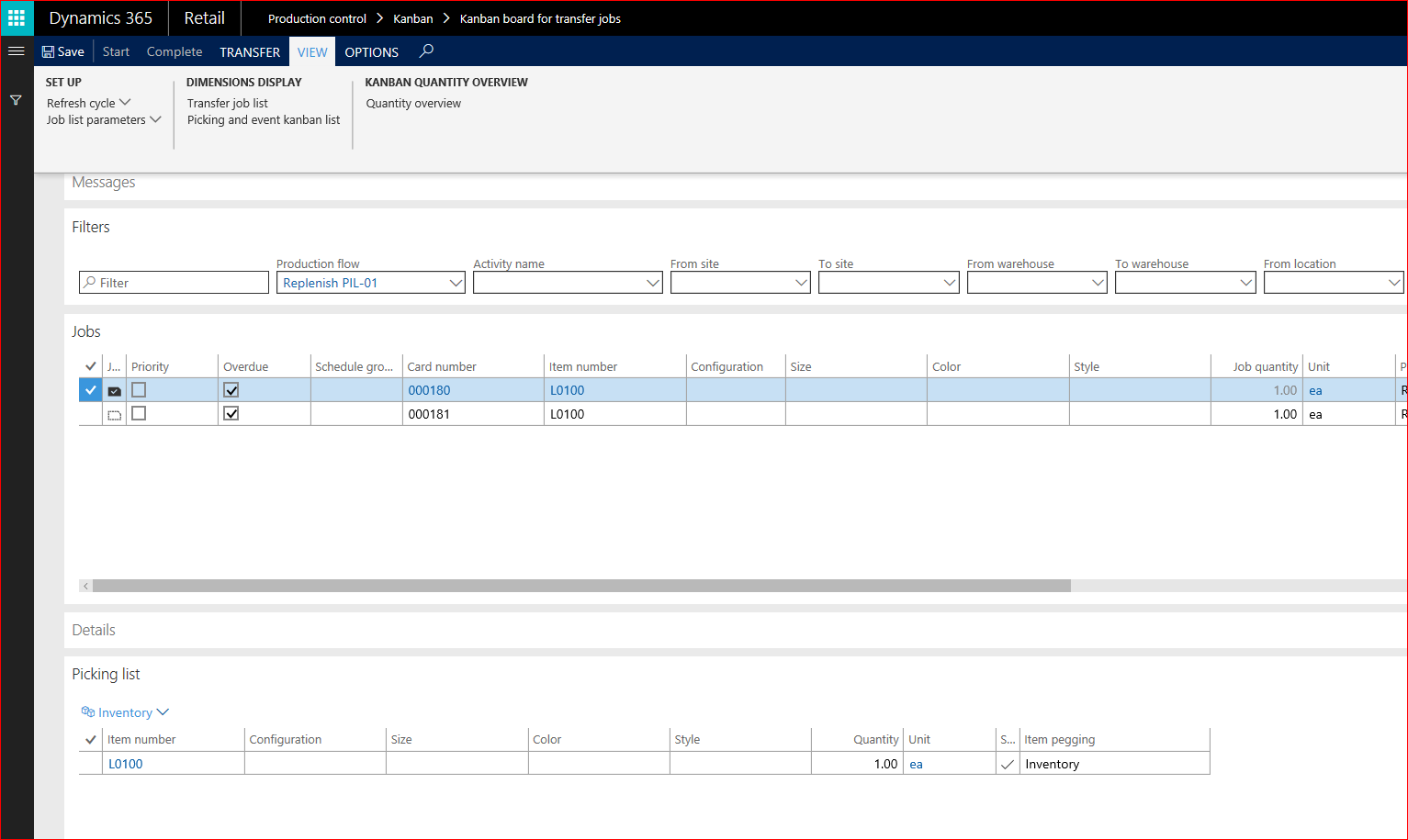

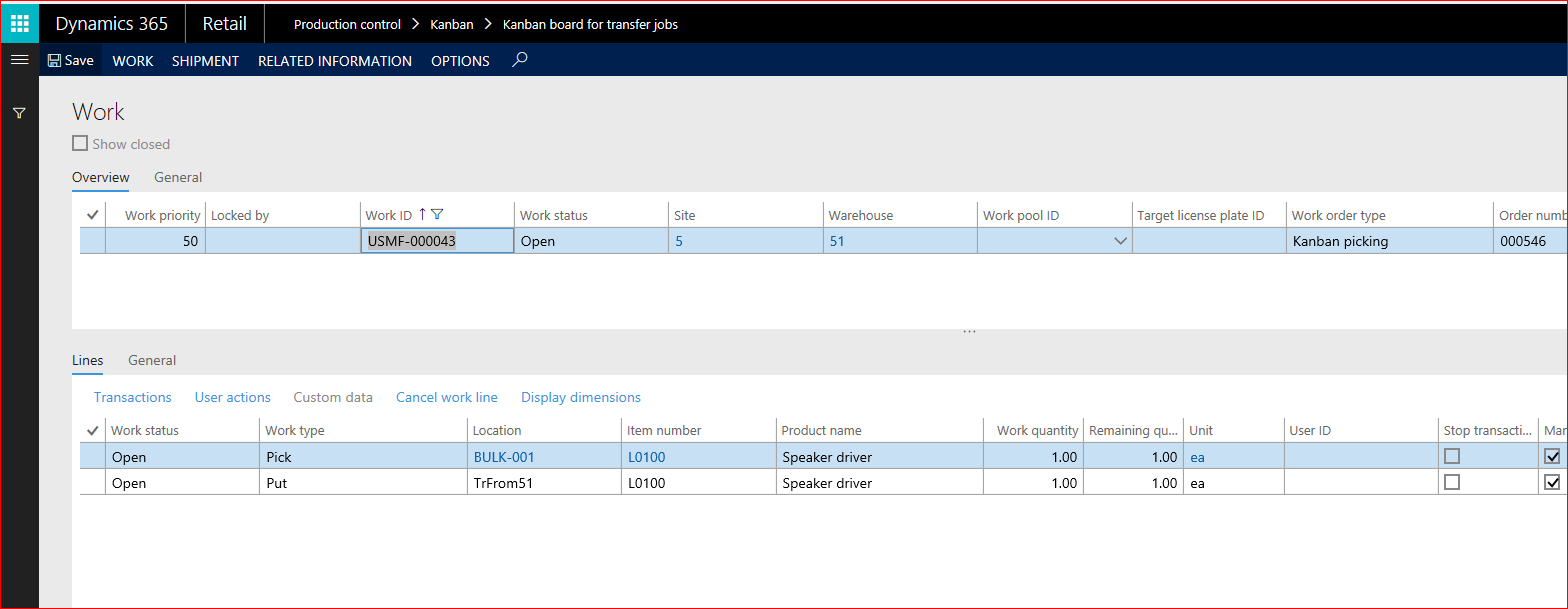

Look in the Work details (Tab: Transfer-> Group: Warehouse -> Work details)

Work of type Kanban picking has been generated to transfer from the bulk location to the transfer location TrFrom51. Tak a note of the Work-ID that you should use later, when you process the pick work on the hand-held device.

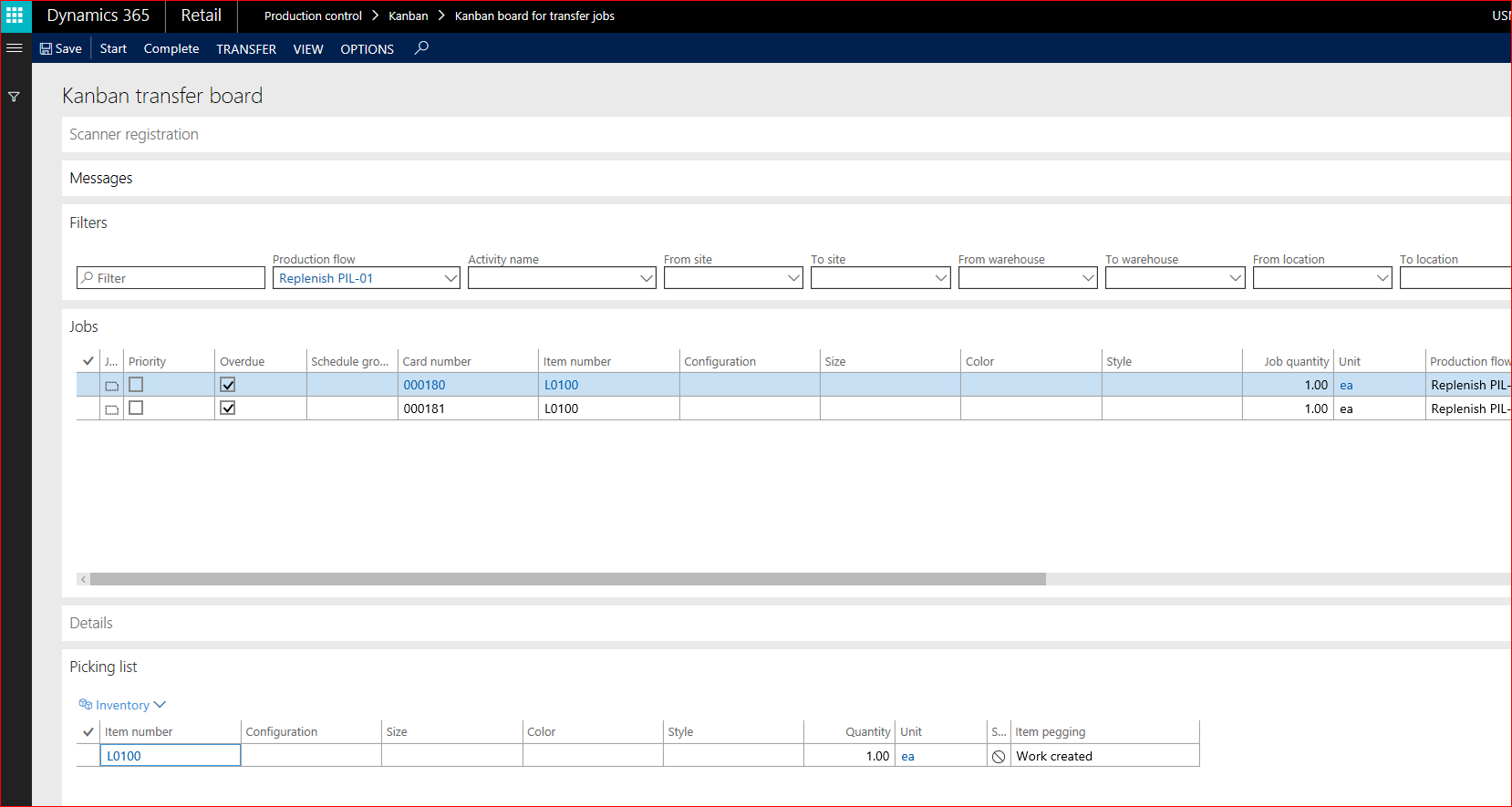

Go to the Picking list section in the Kanban board for transfer jobs

Note: In the picking list section, you can see from the Item pegging status, that Work has been created but not yet processed.

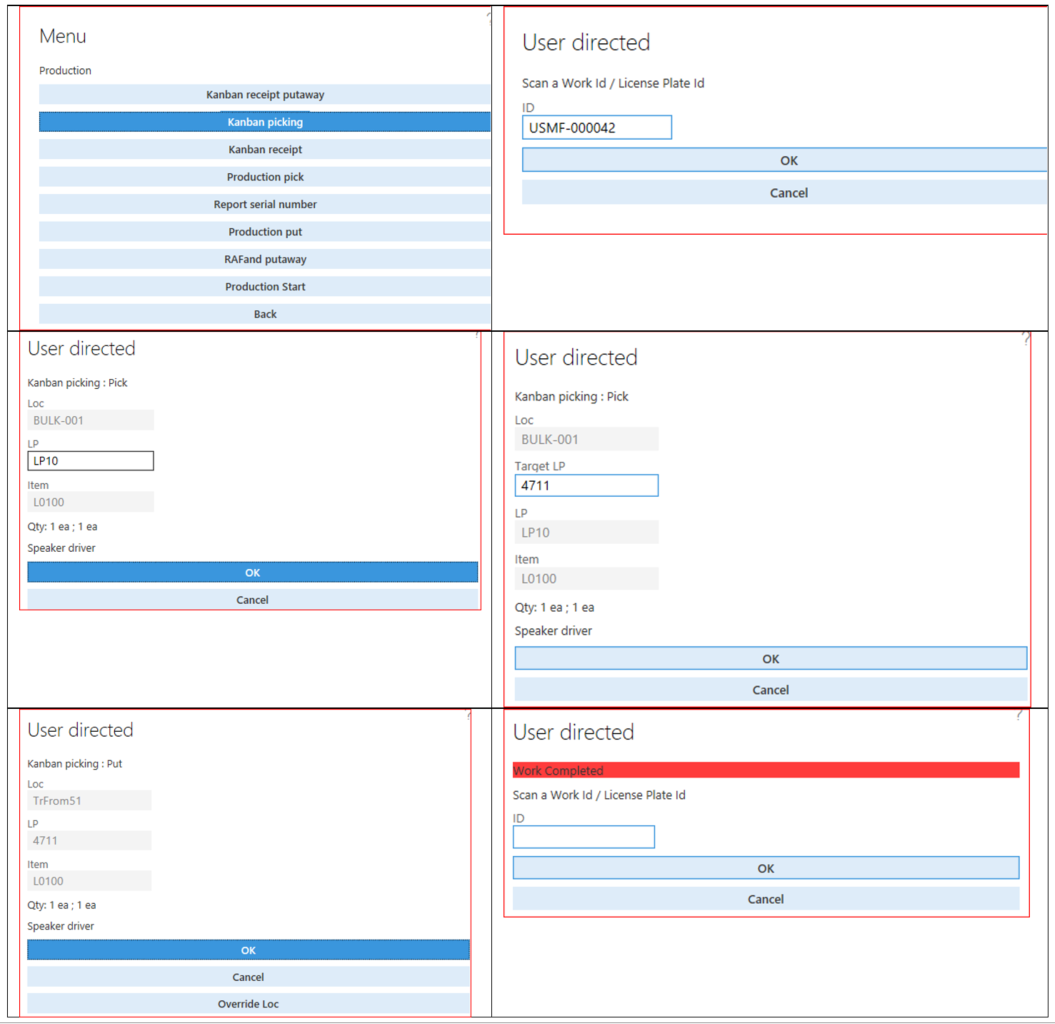

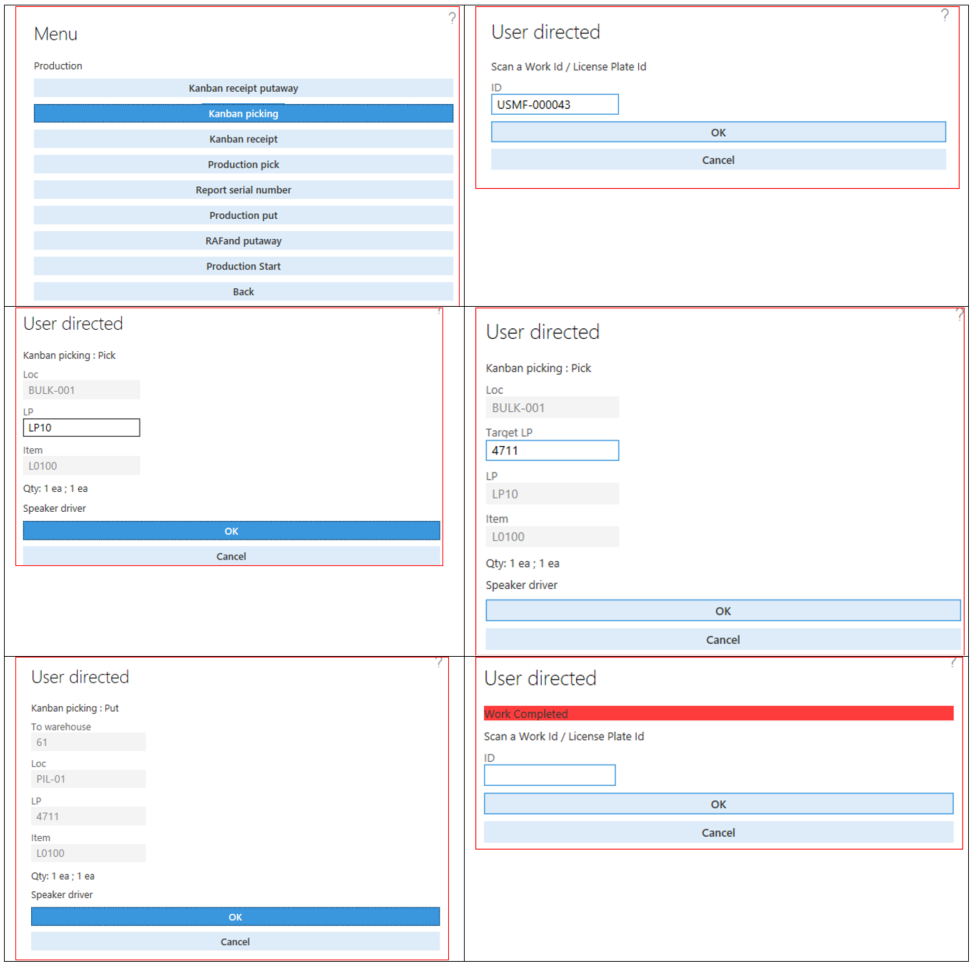

Use the hand-held device to process the pick work for one of the Kanban’s

Go back to the Kanban board and look at the item pegging status in the Pick list section

Note: The status has changed from Work created to Inventory.

From the Kanban board complete the Kanban by selecting the Complete button

L0100 is now transferred to the production input location and is ready to be consumed.

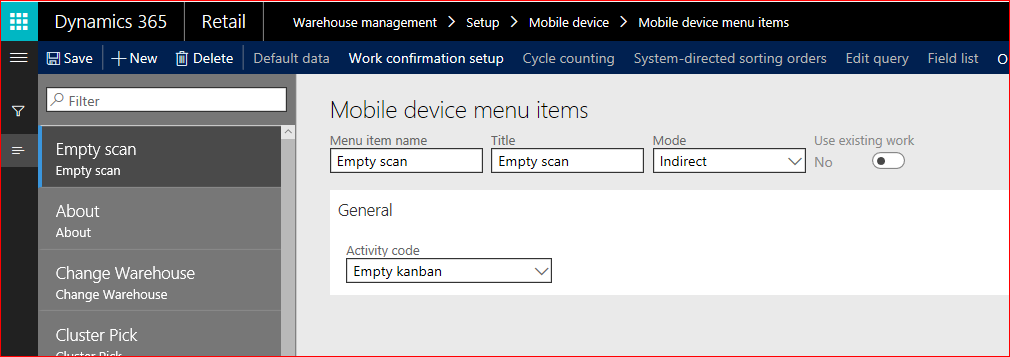

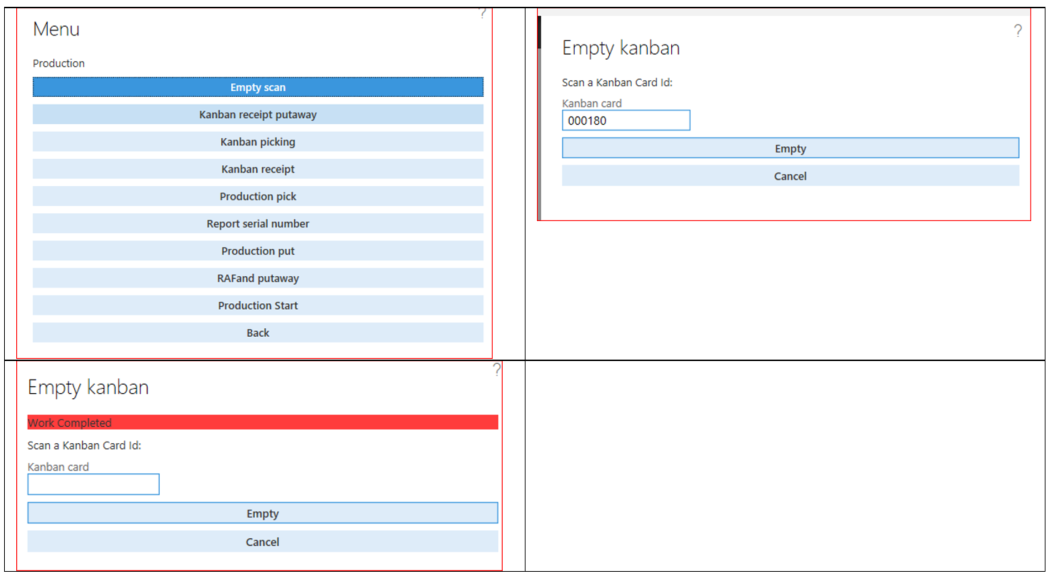

Kanban empty signal

The signal to replenish L0100 can now be given with an empty scan. The empty scan indicates that a Kanban has been consumed at the production location and is now empty. The empty signal can be configured to happen either automatically when a Kanban is completed or as a manual registration. This is set up in the field Register as empty in the Kanban rule (Section: Kanban rule -> Group: Material handling unit -> Register empty). Make sure the Manual (includes scanning empty) option is selected on the Kanban rule for L0100. The Manual empty signal can be done from the Kanban transfer board, but there is also an option to make the make the empty signal on the mobile device. Here is how to configure the empty signal for the hand-held device. First create a new Mobile device menu item with the below settings:

Add the new menu item to a mobile menu, for example the menu for Production.

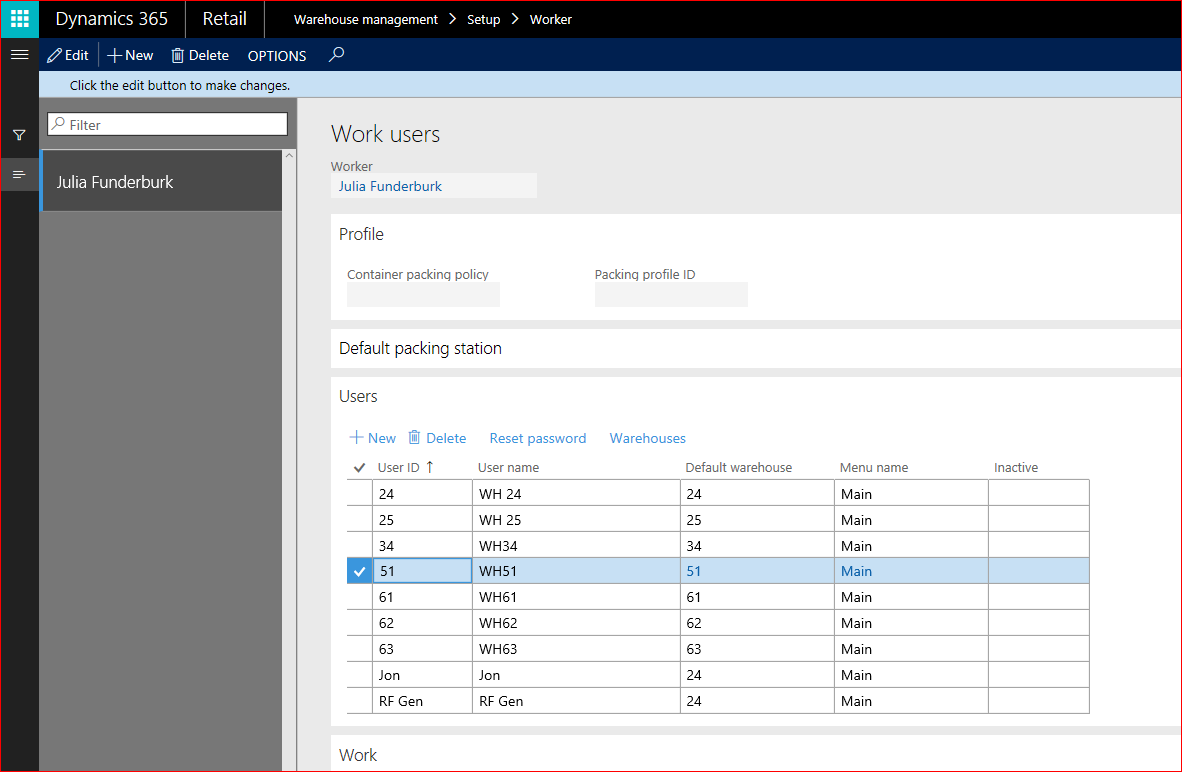

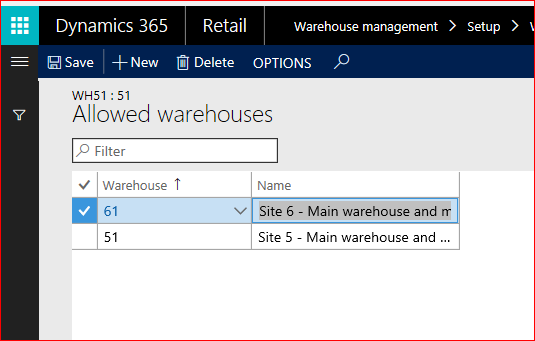

As the material L0100 is now in warehouse 61, we need to change warehouse to 61 on the mobile device. This is done by granting the warehouse worker in warehouse 51 access to also work in warehouse 61 in the Work users page

Select Warehouses in the action pane

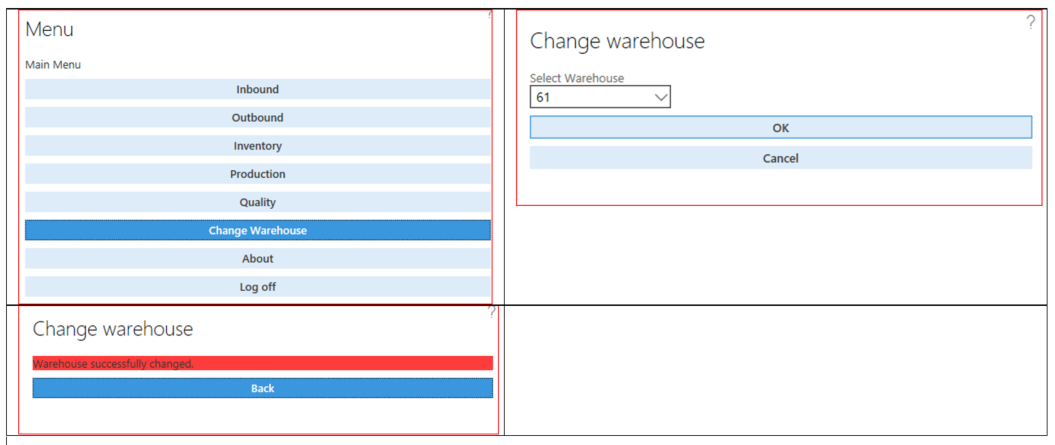

Go to the mobile menu and select Change Warehouse

Select the Empty scan option in the mobile menu

Going back to the Kanban board for transfer job, you can see the new Kanban that was created by the empty signal

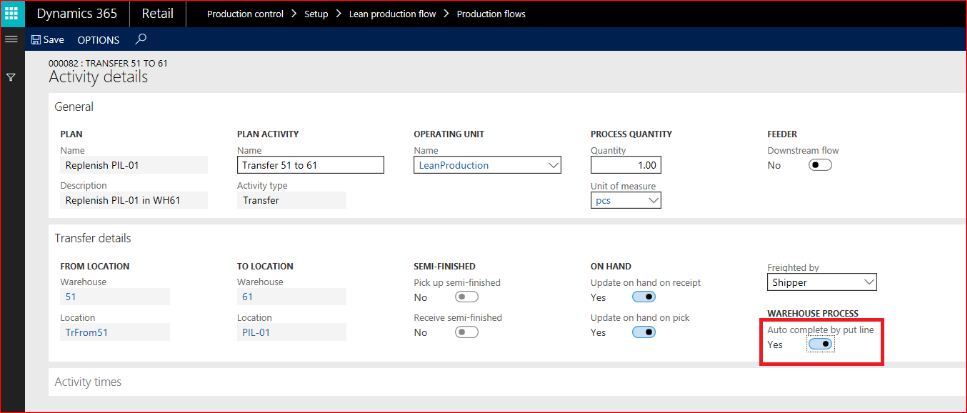

Option to auto-complete the Withdrawal Kanban when completing pick work

There is also an option to setup the transfer activity for the withdrawal Kanban to auto-complete when the put transaction for the Kanban pick work is completed. This option can for example be used if the warehouse worker, who picks the material in warehouse 51, also delivers the material to the production input location on warehouse 61. With this option the hand-held work flow for Kanban picking is first directing the worker to pick-up the material from the pick location in warehouse 51 and then directing him to deliver the material to the put location in warehouse 61. The warehouse worker will not notice that the Withdrawal kanban is automatically completed, when the put transaction is completed.

Go to the definition of the transfer activity in the production flow and select the Auto complete by put option.

Go to the Kanban board for transfer job and find one of the un-processed Kanban's

Open the Work details and note the Work-id

Process the work from the hand-held device (user should be in warehouse 51)

Note: From this flow you can see how the user is directed to put L0100 to warehouse 61 on location PIL-01.

Go to the Kanban board for transfer jobs and verify that the Kanban is completed

Comments

- Anonymous

July 11, 2017

The comment has been removed- Anonymous

October 26, 2017

Hi Paul,Sorry for not coming back before now. Is this still an issue?Best regards,Johan Hoffmann

- Anonymous

- Anonymous

August 21, 2018

Hi Johan,A very good post some amendments because I was struggling a while till it works as shown - First you missed the section to set up the new Location TrFrom51 in WHS 51 and second in the introduction you described the Input Location 001 in WHS 61 but in the Scenario it ist PIL-01